Dear Loyal Safety Briefing blog followers,

Today is the last time I will post items on the safety subject matter HERE. As you may know, Blogger is a free service to Google account holders, and since VSE has created a new home for the blog, I would be constantly double posting everyday. If you would like to continue to receive the daily safety brief, please feel free to check out this web link where I will make all future postings:

http://dailysafetybrief.vsecorp.com/.

On that site, there is an RSS feed subscription button. You can use that to get the articles delivered to your Outlook Inbox when new postings are made. If you aren't sure how to do that, send me an email to rjswigart@vsecorp.com, and put the word "RSS" in the subject line. I will send you complete instructions on how to get these blogs delivered in your email.

Thanks for the support you all give me. Sometimes it is tough to get in front of folks and give a speech, half asleep at 7 am...but in the end, it's worth it..

Sincerely,

Robert Swigart

This is the world wide web location for employees and their friends to get a daily dose of safety. These safety briefs are conducted daily at 7:00 am.

Monday, June 27, 2011

6/27/2011 Individual Quality Makes the Difference

Individual Quality Makes the Difference

In this age of rapid change and need for efficiency, we also see an increased emphasis on quality assurance standards such as ISO (International Standardization Organization) certifications. However, the biggest factor we must consider in this age of more with less, is how we, as individuals, impact the quality process. Our honor and integrity as human beings needs to be confirmed in our work and everything we do. So, you may ask, how does this apply to safety?

Our personal behavior can determine someone else's fate as well as our own. Failure to do things correctly can jeopardize the health and safety of those around us, as well as our own well being. We must beware of letting mediocrity infiltrate our methods. If our methods do not indicate our best effort, they are not good enough. What we do, how we work, and the standards we set for ourselves, makes the difference between success and failure. If we accept mediocrity, we accept failure as a way of life.

Consider the example of an employee at a ship building facility who, at the end of a busy day, left a hammer in the hull of the ship. Fourteen years later, the boat sprung a leak in the middle of the ocean because the hammer wore a hole in the ship's hull over time. The boat sank and lives were lost.

What about the oil that was spilled on the shop floor and wasn't cleaned up right away? A fellow employee, perhaps a friend of yours, comes by moments or hours later, doesn't see the spill, slips and falls. Now he has severe back problems that affect his future, his family, and their quality of life for generations to come. By the way, the expense of that injury is also a major expense to the company, affecting the lives of all the workers and the business owners.

Each time we don't do our best, we accept mediocrity as a way of life. To help set standards of excellence in everything we do we must pay attention to detail. If we don't know the right way to do something, we must ask someone who does. If asked for help, we should take the time to demonstrate how to correctly and thoroughly complete a task. We must make an individual contribution, on a daily basis, to the quality process.

When we set higher individual standards for ourselves and give our best to everything we do, it can make a difference. This helps to protect the finest quality of life this world has to offer.

Friday, June 24, 2011

6/24/2011 Hazards of Solvents

We use solvents practically every day in our lives. At work, we may use or be exposed to solvents when we come in contact with paints, coatings, while using dip tanks, thinners, degreasers, cleaners, glues or mastics. As a result of this widespread usage, it is important to know some of the hazards that are associated with the group of chemicals, generally called "solvents."

For practical purposes a solvent is simply a liquid capable of dissolving specific solids or liquids. As you know, there are solvents that we use daily that are hazardous. Petroleum based solvents are the most common type used in industry. Therefore, as part of your job, it's important for you to understand the hazards of working with or around solvents.

Exposure and over-exposure to a solvent can come from various methods. The routes of entry may include:

• Absorption by direct contact on the skin. If there are no "barriers" between the solvent and your skin, the solvent can be absorbed through your skin.

• Inhalation by breathing solvent vapors. Breathing in the solvent vapors can quickly result in the chemical getting into your body and bloodstream via your lungs.

• Ingestion from literally eating the chemical by not practicing good hygiene after handling solvents. Direct contact with your hands and mouth through eating or smoking may result in unexpected ingestion of solvents.

• Puncture of the skin by a tool or other object which has a coating of solvent. Punctures can result in the direct introduction of toxic chemicals into your body.

Overexposure to solvents can cause a variety of ailments. Depending on the type of solvent you are exposed to, the body will react in different ways. Skin contact may result in minor skin rashes or an allergic reaction resulting in "chloracne." This happens when the solvent dissolves the skin's natural oils. Some workers can develop a sensitization to a particular product or chemical. Sensitization results in the entire body being "overly" sensitive to a particular chemical or product. After sensitization has occurred, even a very slight exposure can result in adverse or serious reactions. Serious overexposures can lead to illnesses resulting in organ or tissue damage.

As with any chemical or product, important information is contained in the product's Material Safety Data Sheet (MSDS). The MSDS provides information on safe use, handling, disposal and protection methods among other information.

Solvents are very useful in our everyday lives. If we take the time to learn more about them, we can be better prepared to properly use them, protect ourselves and effectively get our job done.

If you are unsure of the solvent or product that you are using, ask questions or check the MSDS.

Thursday, June 23, 2011

6/23/2011 Lyme Disease Safety Tips

| Click above for larger image |

Lyme Disease Safety Tips

Lyme disease is passed on to humans through the bite of a deer tick. They are generally small brown ticks that are found in grass as well as wooded areas. They can be in the middle of a forest or in your front yard. In 2010, it was reported that nearly 30,000 people were bit by a deer tick and contracted Lyme Disease. You should use extreme precaution in woods and areas with grass and bushes during the late spring and summer months when the ticks are most active.

The best way to protect yourself against Lyme Disease and other tick-borne illnesses is to avoid tick bites. This includes avoiding tick-infested areas. The most common occupations that should follow Lyme Disease safety tips are farmers, loggers, landscapers and park rangers. But, you can also be exposed away from work if you hunt, fish, camp, do yard work, or participate in hundreds of other outdoor activities.

Symptoms of Lyme Disease

There are several symptoms of the disease that will help you decide if you should seek medical attention.

1. The most common symptom of Lyme Disease is a red rash that looks similar to a bulls-eye. It can show up anywhere from hours to weeks after the initial bite from the tick.

2. Fatigue

3. Fever

4. Headache

5. Sore Throat

6. Muscle Aches

7. Joint pain

Lyme Disease Prevention Tips

If you live in, or visit wooded areas, or areas with tall grass and weeds, follow these precautions against Lyme Disease and other tick-borne diseases like Rocky Mountain spotted fever, ehrlichiosis and tularemia:

• Use insect repellent with at least 20% DEET on yourself each time you work in exposure areas.

• Wear long sleeve shirts and pants. Tucking your pants in to your shoes may prevent ticks from climbing up your leg through the bottom of your pants.

• Wearing light color clothes will make it easier to spot ticks that may be on your body.

• Once you get home check your entire body for ticks that may have got through your clothing. Check under your arms, your scalp and groin as well as all your other body parts.

• If you find a tick it should be removed with a pair or tweezers. Folk remedies for tick removal tend to be ineffective, offer no advantages in preventing the transfer of disease, and may increase the risks of transmission or infection. The best method is simply to pull the tick out with tweezers as close to the skin as possible, without twisting, and avoiding crushing the body of the tick or removing the head from the body. The risk of infection increases with the time the tick is attached, and if a tick is attached for less than 24 hours, infection is unlikely. However, since these ticks are very small, especially in the nymph stage, prompt detection is quite difficult.

• If you are working beneath trees or high bushes wearing a hat will help reduce the risk of ticks in your hair.

• Never wear sandals or open toe shoes in areas where ticks could thrive. Wearing work boots that go past your ankles and are kept tied tightly will keep ticks from getting on your feet.

These Lyme disease safety tips should keep ticks off of your body while you are working. If you think your have been bitten by a deer tick and may have been exposed to Lyme disease, make an appointment to see your doctor immediately.

Wednesday, June 22, 2011

6/22/2011 Infectious Disease & First Aid Treatment

- One of the best ways to protect yourself when giving first aid is by wearing rubber or latex gloves. This not only protects you, but protects the injured person from additional risk of infection as well. Even small finger cuts or abrasions on your hands could provide entry for a virus or bacteria.

- All first aid kits should be stocked with rubber gloves that are packaged individually so they remain sanitary. Gloves should never be re-used.

- First aid kits should also be stocked with face masks and glasses. If there is a chance of blood splattering, cover your mucous membranes-mouth, nose and eyes-with a mask and goggles. A dust mask or respirator will do in a pinch.

- Mouth-to-mouth resuscitation offers another potential for exposure to infectious disease. You can protect yourself through the use of a disposable microshield or S-tube, as they are sometimes called, which should also be supplied in first aid kits. These plastic devices prevent saliva transfer and limit the potential for infection from a variety of infectious diseases.

- Blood-contaminated gloves, clothing, bandages and absorbent materials should be properly deposited in leakproof containers that are clearly marked with the red biohazard symbol.

- Wash hands and other exposed skin immediately and thoroughly with soap and warm water if you've been exposed to blood or body fluids. To be safe, you should also be tested for pathogens.

- When bleeding occurs in the workplace, the area of the spill should be disinfected. A mild solution of water and household chlorine bleach (10-to-1) is an accepted method. Someone who touches a blood spill even hours later could be subject to infection if disinfectant isn't used.

With hard-to-combat infectious diseases on the rise, take no chances!

Tuesday, June 21, 2011

6/21/2011 Watch Your Step!! Don't Slip & Fall

Watch Your Step!! Don't Slip & Fall

Slips and falls are one of the most frequent causes of accidents, both on and off the job. Each year in the United States, more than 300,000 people suffer disabling injuries from falls. Slips and falls can be fatal as well; they rank second only to automobile accidents, causing nearly 12,000 deaths a year. To avoid getting hurt from falls, avoid rushing and remember the following:

WATCH WHERE YOU WALK

Be aware of where you are walking. Look down continuously for spilled liquids, materials, equipment, changing surface levels, etc. Make sure the area is well-lit or use a flashlight if lighting is poor.

WEAR PROPER FOOTWEAR

Make sure your shoes are in good shape and correct for the job. Discard worn-out shoes with smooth soles and other defects. If conditions are wet and slippery, wear non-slip shoes or boots. Avoid footwear with leather soles which have poor floor traction--especially on smooth surfaces.

CHECK FLOOR OPENINGS

Avoid unguarded floor openings. On construction sites, when covers are placed over floor openings, avoid walking on the cover unless it is absolutely secure and will not move or collapse. Never jump over pits or other openings.

BE CAREFUL ON STAIRS

Do not run when going up or down stairs. Check to see that stair treads are in good shape, with no obstructions on the steps. Always use the hand railings that are provided. Avoid carrying large loads when going up or down stairs and ensure that stairs are well-lit.

USE LADDERS CORRECTLY

Never use broken or defective ladders. Set the angle of the ladder at the proper four-to-one ratio (height to width angle). Make sure the ladder is on solid footing and will not move when you climb upon it. Whenever possible, tie your ladder to the structure to improve stability. Anchorage at the bottom is also a good idea. Never stand on the top two steps of a step ladder.

MAKE SURE SCAFFOLDING IS SAFE TO USE

When working on scaffolding, make sure it is secure, stable and properly set-up. Do not work on scaffolding if guard rails are missing or the base is unstable. Check to see that planks are in good shape and not cracked. Tall scaffolds should be tied into a structure to increase stability.

DON'T JUMP OUT OF VEHICLES

Never jump from equipment or vehicles. Use the handrail and steps provided, remembering the "three point rule." Avoid stepping onto loose rocks, slippery surfaces, oil spills, etc.

Watch your step and don't trip yourself up! Remember, Gravity Always Wins!

Monday, June 20, 2011

6/20/2011 Hydraulic Hoses and The Danger Of Leaks

Hydraulic Hoses and The Danger Of Leaks

You may find it hard to believe, but hydraulic hose assemblies are not designed to leak--though sometimes they do. And when they do, something is wrong. Leaks from high-pressure hydraulic lines are not just messy, they are dangerous. Leaks create slip and fall hazards, fire danger, and they contaminate the environment. Leaks can cause skin burns and, under high pressure, can penetrate the skin. The most common causes of leaking hoses are abrasions and improper assembly. If you work with hydraulic hoses, you should become skilled at anticipating problems, preventing them and fixing them.

Preventing Problems; prevent abrasion by using hoses of the correct length and diameter. Run the hose in the manner specified by the machine manufacturer, making sure it is supported and restrained by all provided hangers and/or brackets. If chaffing guards were originally installed but missing, they must be replaced. Do not ignore a damaged outer jacket. This allows moisture to attack the exposed hose reinforcement, leading to rust. Corrosion could lead to hose failure.

The Wrong Way to Find and Fix Leaks: What do you do when you find a leaking fitting? Find a wrench and give the fitting another turn? That extra turn could cause a greater leak or cause the fitting to fail entirely. Do not use your hand to find the leak. Use a piece of cardboard or wood instead. Hydraulic fluid is hot and can burn the skin. A pinhole leak, under pressure, could actually inject fluid under your skin, causing poisoning, infection, and threaten life and limb. It can and has happened.

Test for Tightness: But before doing this, shut the machine off and bleed hydraulic pressure from the line. If the fitting threads were to strip or a connection was to fail under pressure, injury or fire could result from the sudden release of hot oil. The usual cause of a leak at a fitting is improper assembly or damage. Make sure that:

(1) Both ends are clean inside and out, and that no physical damage has occurred;

(2) New seals are used and they have been cleaned and lubricated before installation;

(3) Fittings are not over-tightened--which can distort seals and ferrules, causing metal fatigue or cracking flared ends;

(4) Fittings are compatible. There are many different thread ends, and some may almost go together properly, but not quite.

Proper Assembly Of Hose Ends Is Important. Hoses that come apart under pressure can whip back with great force and release a lot of hot oil. If the failure occurs at a fitting, the usual reason is improper crimping, an incorrectly cut hose, or a stem that was not inserted into the hose all the way. If you assemble your own hoses, check your crimping dies for wear. On some types of crimping machines, if the dies become worn, the crimp is looser than it should be. Screw type hose clamps are not to be used on pressurized hydraulic hoses.

People who work with any type of fluid piping system know it takes clean, careful workmanship to prevent dangerous leaks. If you see a leak, report it. If your job requires you to fix leaks, do it properly and safely.

Friday, June 17, 2011

6/17/2011 Water Safety - On & Off the Job

Water Safety - On & Off the Job

Whether you are working or enjoying recreational activities in, on, or near the water, the best water hazard insurance you can have is learning to swim, and teaching your family to swim. You do not have to be a champion swimmer in order to save yourself in a water emergency. A simple stroke such as a dog paddle can enable you to reach safety. American Red Cross statistics reveal that one half of the annual drowning incidents happen within 30 feet of safety.

Water safety begins with good judgment. Never work alone near water, or swim alone. Know the area where you are working or swimming and do not exceed your ability. Know where the swift currents are. Find out about drop-offs, deep holes, and rocky areas. A few common sense items that could save your life are:

• Wear flotation devices while working on docks or piers, or while boating. Always keep them buckled, snapped or zipped, so if you fall in, they will stay on.

• Do not mix drinking and swimming at picnics or outings. Over ten percent of all drowning victims had consumed alcoholic beverages.

• Swimming requires a lot of energy and makes muscles susceptible to cramps. If you lose energy, rest on your back in a floating position, and use a minimum amount of motion.

• Undertow or strong currents: There are several types of dangerous marine currents that should be avoided, if possible. If you are caught in a current, do not fight it. Swim parallel to the shore or diagonally toward it, heading shoreward only after you are out of the current.

• Water Temperature: Cold water can cause shock to the body. Blood vessels constrict, your body loses heat, and you can develop an oxygen deficiency that causes unconsciousness and ultimately drowning. Hypothermia caused by cold water can cause death in minutes.

• The old saying you heard as a child is true - Don't go swimming immediately after eating or any vigorous exercise. This may cause severe cramps.

• Stay with a swamped boat or canoe. Many boats will not sink even if the hull has been ruptured, and they may still offer some buoyancy. Sometimes you can climb or swim into the swamped boat and paddle to shore. It is also easier for emergency rescuers to find you if you are close to the boat.

• Consult with your local municipality, Coast Guard office, American Red Cross office, and other authorities for additional water safety tips, local rules and regulations.

Finally, abide by the safety rules at all times-on and off the job-when around the water. Share these rules and enforce them with your family.

Do not let a drowning tragedy strike your workplace, or any members of your family.

Thursday, June 16, 2011

6/16/2011 Afterthoughts and Regrets

Afterthoughts And Regrets….

How often have you said or done something and then later, reflecting on your action, thought to yourself, "How could I have done that?"

Here are some afterthoughts which, unfortunately, too many of us have experienced:

•"That's how we've always done it before." (…before the accident occurred anyway.)

•"I never thought that a little bolt dropped from that distance would cause so much bleeding." ( I should have worn a hard hat, I guess.)

•"If I had taken that first-aid/CPR course, I probably could have helped him." (…and chances are, he would still be here.)

•"I should have taken care of that board with the projecting rusty nails earlier." (Now, I have to take off work to get a tetanus shot.)

•"Wow, I never realized that a fire could get out of control so fast." ( If I'd called the fire department before trying to put it out myself, I might still have a place to work tomorrow.)

•" I know they were always preaching that we should lift with the leg muscles instead of the back muscles." (What the heck is a herniated disk?)

•"For few more dollars, I could have bought safety shoes." (That deep cut in the toe section ruined my new work boots, and this broken toe still hurts.)

•"My safety glasses were in the tool box, but I was just going to grind off this one little piece…." ( I wonder if they'll still let me drive with only one eye?)

•"We were only going to use the scaffold for one day. I never thought a hammer would fall off the plank and strike someone." (I had a hunch I should have taken the time to install the toe boards.)

•"They always insisted that the tool rest should be no more than one-eighth inch from the grinding wheel. What difference does another quarter inch make?" (I was lucky not to go blind when the chisel got wedged and the wheel exploded into a thousand pieces.)

Any of this sound familiar?? They say hindsight is the only perfect science-but foresight could have avoided these incidents, misfortunes and regrets.

Learn from others' mistakes and you'll have no regrets!

Wednesday, June 15, 2011

6/15/2011 The Hazards Of Silica Dust

|

| Click on image for larger |

The Hazards Of Silica Dust

Crystalline silica is a common mineral in the earth's crust, and is found in many types of rock including sand, quartz, and granite. Silica is present in both work and non-work environments, and exposure to crystalline silica dust has long been known to cause a disease called silicosis. When you inhale crystalline silica the lung tissue reacts by developing fibrous tissue around trapped silica particles. This condition of the lung is called silicosis.

Due to the extensive use of concrete and masonry products in buildings today, construction workers have a potential exposure to crystalline silica. Operations such as dumping of rock, jack hammering, abrasive blasting, sawing, drilling or demolition of concrete and masonry structures are some of the activities that could produce this exposure.

Silica sand or other substances containing more than 1% crystalline silica should never be used as abrasive blasting materials. Where silica exceeds 1% of the content, less hazardous materials should be substituted. In addition, always follow safe work practices when there is possible exposure to silica dust.

FOR APPROPRIATE PROTECTION:

o Keep awareness high--which is the key to preventing silicosis. Recognize when silica dust may be generated and plan ahead to eliminate or control the dust at the source.

o Use proper respiratory protection when point of operation controls cannot keep exposures below the recommended exposure limit.

o Use Type CE pressure-demand, or positive-pressure, abrasive-blasting respirators when sandblasting.

o Always use dust control systems when they are available and keep them well maintained.

o Be aware that high silica concentrations can occur inside and outside enclosed areas during operations such as concrete or masonry sawing or abrasive blasting.

o Do not eat, drink, or smoke in areas where sandblasting is being done, or where silica dust is being generated.

o Wear disposable or washable over-garments at the work site.

o Wash your hands and face before eating, drinking, or smoking and vacuum (don't blow) dust from your clothing.

Lungs take care of normal dust. Airborne dust and dirt is common at worksites--both at home and on the job. Fortunately, the body's respiratory system does a good of job filtering out dust and most foreign bodies. Fine particulates such as asbestos and silica, however, are so tiny they can get past our filtering system. This may cause serious lung problems over an extended period of time if protection or controls are not used.

Respect these tiny invaders. Use the appropriate personal protective equipment and safety precautions.

Tuesday, June 14, 2011

6/14/2011 Safety Considerations For Sand Blasting

Sand blasting operations can be overlooked when preparing safety plans because they are generally a small part of a larger project such as cleaning and refinishing or painting. As a result, many workers are exposed to the hazards of sand blasting without adequate protection. Even if all sandblasting equipment is properly designed and regularly inspected, users must always be alert to the hazards of these operations and take precautions against harmful exposures.

Airborne dust: This is one of the most serious hazards associated with blasting operations. When evaluating this hazard, it's important to consider the concentration of dust and the size of particles. Larger particles, considered "nuisance" dust, are normally filtered out in the nose and throat. Smaller particles (10 microns or smaller) can bypass the lung's filtering system and penetrate deep into the respiratory system, where they may cause serious damage. Safeguards are needed when smaller particles are present in the working environment.

Metal dust, in addition to the abrasive being used, contributes to the generation of airborne dust. Metals such as lead, cadmium, and manganese, can be extremely toxic when inhaled. Many existing paints have a lead base. Regulations require special handling, trained personnel, and medical monitoring when lead is present. If in doubt, check it out. Don't guess.

Silica sand: This product is a potentially serious health hazard and should not be used as an abrasive. If silica containing (quartz) materials are selected for any reason, workers must wear a positive pressure or pressure demand respirator with an assigned protection factor (APF) of either 1000 or 2000. Silica must be contained and disposed of properly. Even if a wet blasting method is selected, silica that is allowed to migrate by either wind or water, will eventually become an airborne contaminant.

Air supply: Air-supplied respirators must be used (1) when working inside of blast cleaning rooms, (2) when using portable units in areas without enclosure, and (3) under any circumstances where the operator is not physically separated from the abrasive material by an exhausted enclosure. If fresh air line respirators and compressors are used, make sure the intake hose is placed in an area that provides clean air. An attendant should be in the area at all times, monitoring breathing air and assuring the blaster's safety.

Additional personal protective equipment: Blasting operations inside a blast booth create high noise levels, so hearing protection is a must. Operators should also use heavy canvas or leather gloves, aprons, or leggings when appropriate, as well as safety shoes.

Manual cabinet blast cleaners should never be exhausted into an area where workers can breathe dusts. These fully enclosed cabinets are designed to filter out dust and re-use blasting medium.

Handling and storing abrasives: Dust is nearly always created at any point where abrasives are transferred, whether by hand or shovel. Therefore, all points of transfer must be properly exhausted and workers who handle abrasives manually should wear particulate filter respirators.

Be aware of what is in the air!

Monday, June 13, 2011

6/13/2011 What To Do About "Near Misses?"

|

| Click on image to view larger |

What To Do About "Near Misses?"

Unlike a western gunfight "shoot out" at the corral on television, serious accidents can cause real anguish and suffering so real and vivid that persons involved or nearby bystanders rarely forget the flow of blood, broken limbs, crushed bodies, or screams of pain. An accident without injury though is more like the bloodless, painless fakery of television "violence"-perhaps without real purpose in the drama, and therefore easy to forget.

In real life there is a danger in brushing off accidents that do not hurt, harm, or damage. When these accidents, or perhaps we should refer to them as near misses, happen we should immediately run the red warning flag up the pole. Because a non-injury accident is like a 104 degree fever, it's a positive sign or symptom that something is wrong.

Sometimes we misdiagnose or completely fail to diagnose the symptoms of near misses, because luck or blind chance saved us from injury. We may tend to shrug it off and forget the near miss with a casual kind of ignorance. Hopefully everyone agrees that it is not a good practice to rely on luck for effective accident prevention.

One of the best ways to eliminate the likelihood of future close calls is through effective root cause analysis and effective corrective action taken on near misses. A list of near misses can be almost endless: lack of proper machine guarding; improper maintenance or grounding of equipment; missing handrails or guardrails; poor housekeeping; improperly stored material; stubbing a toe on a protruding floor object; bumping up against a sharp object; or tripping over clutter and almost falling down. It's best to learn the real lessons from these near misses, since they are very likely to continue to occur repeatedly until an injury occurs.

There was a study done many years ago that found for every serious or disabling injury reported, there were about 10 injuries of a less serious nature, 30 property damage incidents, and about 600 incidents of near misses with no visible injury or property damage. This study was part of the foundation for the widely accepted accident prevention theory that "increased frequency leads to severity."

How can you help? Report each and every near miss incident to your supervisor immediately in order to help prompt investigation and follow up actions that will reduce the potential for future near misses. Supervisors must partially rely upon you and your fellow workers to report these to them as they just can't see everything.

If you are involved with or witness a near miss incident, remember that you or your co-worker may not get a second injury free chance to hoist that red warning flag up the pole. Do your part to help make the workplace safe for everyone involved.

Report those near misses to your supervisor immediately!

Friday, June 10, 2011

6/10/2011 Head Injuries - After The Fall

|

| Click on Above Image to View Larger |

HEAD INJURIES - AFTER THE FALL

You can work for years and hardly get a scratch, then one day a fall can turn your life around. Fall injuries may cause abrasions, fractures and dislocations. However, one of the most serious results of a fall, other than death, can be a head injury. How this will affect you depends upon which part of your brain has been injured as a result of a fall or impact. Broken bones usually heal, but head injuries can result in lifelong serious problems, such as:

• Changes in personality, such as increased anxiety, depression or anger.

• Difficulties with eye and hand coordination, and inability to handle tools or play sports well.

• Defects in vision and visual illusions.

• Short-term memory loss or interference with long term memory.

• Increased aggressive behavior.

• Difficulty in distinguishing left from right.

• Changes in social behavior

How You Fall Often Determines Your Specific Injury.

From the time a worker loses a secure grip, footing or balance, until impact, several factors influence what part of the body will be injured and how severe the damage will be. They are:

• Distance of the fall - momentum and velocity affect the impact on your body.

• The angle of the body at impact - we're not like cats landing on all fours.

• The obstacles the body strikes - what if you fall on railings, steps, or vehicles?

• The surface eventually landed on - will it be a pile of hay, or broken concrete & re-bar?

What You Can Do: THINK!

• Help remind your co-workers to play it safe and avoid taking risks.

• Report unsafe conditions to the nearest supervisor.

• Make it a habit to work safely, regardless of time pressures and productivity goals.

• Practice caution at home - accidents and head injuries from falls happen more often off the job than at work.

• Know how to use fall protection and fall restraint equipment. Never say, "I don't need to fool around with that stuff-I'll only be up there a minute."

Stay Alert!

Head injuries can have devastating consequences that may impact your life forever.

Thursday, June 9, 2011

6/9/2011 Unsafe Acts

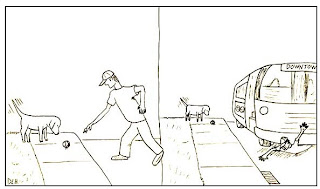

|

| Too appreciate this, click the the picture for a larger image. |

UNSAFE ACTS

Most of us know that accidents are caused by only two things - unsafe acts or practices, and unsafe conditions. Some of us even know that 9 out of 10 accidents are the result of unsafe acts, or things we do when we know better. This is kind of strange if you think about it. We have more to fear from our own actions than from any other job hazards around us. Why do we deliberately expose ourselves to injury every day?

It Won't Happen To Me

Basically, most of us are just thinking about getting the job done and we tend to rationalize the risk of getting injured. We think to ourselves that we have done this job many, many times this way and nothing bad has happened. Therefore, nothing bad will happen to us today. On an intellectual level, we realize there is a potential danger, but decide that the risk of being injured is low. Because we have not been injured so far, we actually think of ourselves as being very safety conscious. We know the right way to do it, we realize that it is hazardous to do it this way, but what we are really thinking to ourselves is "it won't happen to me."

We Take Short Cuts

Some of us are fairly meticulous about following safe work practices, but because a job "will only take a minute" we use an unsafe method or tool. For example, not putting on our safety glasses or wearing hearing protection because the job will only take a minute, or not locking out a machine because an adjustment will only take a second.

Usually we think about it just before we do something a little unsafe, or maybe quite a bit unsafe. We know better, we know the safe way to do it, but we take that little chance. In effect we are saying, "I know that this could result in an injury, but "it can't happen to me." Maybe it's human nature to think that accidents always happen to someone else, but they can happen to you too. What makes you different?

Why take a chance in the first place? Only you can decide to take the time to do your job safely and correctly the first time.

Wednesday, June 8, 2011

6/8/2011 Hazard Awareness

HAZARD AWARENESS

A hazard is defined as a condition or changing set of circumstances that presents a potential for injury, illness, or property damage. The potential or inherent characteristics of an activity, condition, or circumstance which can produce adverse or harmful consequences.

An accident is defined as an unfortunate event often the result of carelessness or ignorance. An unforeseen and unplanned event or circumstance usually resulting in an unfavorable outcome.

There are some key words in these definitions: Unplanned; Unforeseen; Unfortunate; Unfavorable and most importantly POTENTIAL!

For an unplanned or unforeseen event to take place, there has to be potential!. Complacency and taking things for granted are causes of a tremendous number of injuries each year. Recognizing hazards and doing something about them is everyone's responsibility!

So as you begin work, ask yourself:

• Do I have the right tools/equipment for the job?

• Have I inspected my tools/equipment to make sure they are in good repair or am I trying to get by?

• Is the work laid out to provide safe completion of the job?

• Are the materials I am using safe, and do I need additional personal protective equipment such as: safety glasses, gloves, hard hat, respirator, etc.?

• Is there a safer way to accomplish the task?

• Are all necessary equipment guards in place?

• Are written procedures such as lockout/tagout being followed?

Be aware of the potential hazards associated with your work and make your choices carefully!!

Tuesday, June 7, 2011

6/7/2011 Carelessness

CARELESSNESS

Have you ever done anything stupid, something that you know puts you at increased risk of injury? When you realize how stupid you were, whether you got hurt or not, do you ask yourself, "Why did I ever do that?" For your own future preservation, this should be a very important question for you to answer yourself. Consider the fact that approximately 20% of injuries are due to unsafe conditions and 80% are caused by unsafe acts. If you realize that most unsafe conditions are brought about by human failure, then virtually all accidents are brought about by unsafe acts. Why did you do something in an unsafe manner? To answer this question, you will need to put personal defenses aside and know that blame may lie within yourself. Also realize that there may be more than one reason for your actions and others may be involved.

If you knew the proper, safe way to the do the job, then you cannot claim ignorance. What is left, whether you like it or not, is carelessness. So what can cause you to temporarily disregard your own safety?

External Pressure -- "Let's get this job done!" Usually this pressure comes from your direct supervisor. Disregarding safe practices is not going to save enough time to make a significant difference. However, any accident or injury is guaranteed to have an effect. As a matter of fact, when the pressure is applied, it is worthwhile to pay more attention to safety because we know, from experience, such situations frequently lead to more accidents.

Bad Habits -- You fail to follow the established procedure and you don't get hurt (or you were not caught) this time. Psychologically, this is a reward and so you do it again and again and again. But it is also Russian roulette. How many times can you pull the trigger before a round is in the chamber? You know, sooner or later, something is going to happen. There is only one way to stop it - stop pulling the trigger. Do yourself a favor and follow the established procedures.

Internal Pressure -- There is just so much to do and not enough time!" Are you self-motivated and self-directed? Most employers love this type of individual, but your single-minded determination to get the job done may cause you to lose sight of the dangers around you. Think of it this way, you will not finish the job if you get hurt. You may finish the job if you don't get hurt. Therefore, first, prevent injury. Second, work to complete the job. Make sense?

Attitude -- "This safety stuff doesn't apply to me!" So what makes you so special? A study of mine accidents involving foremen showed that the foremen were injured when they personally failed to apply the safety standards they were to enforce. Did the fact that they were foremen protect them from injury? No. Humans are humans. Rich or poor. Black or white. Men or women. Strong or weak. There is nothing in your status that will protect you from injury except following the safe procedure.

Remember, safety is no more than doing the job the right way, every day.

Monday, June 6, 2011

6/6/2011 Life Changing Injuries

Life Changing Injuries

Life changing injuries are those injuries that will change our life and impact our co-workers, families and friends. These injuries would be things such as broken bones, amputations, loss of vision, partial or full immobility of a limb. Injuries that will truly change your life and the lives of those of loved ones. Some of you have had life changing injuries or may know someone who has had a life changing injury. You know the pain, suffering and trauma that they cause. They disrupt just about every aspect of your life.

Everyone I want you to tuck your thumb into the palm of your hand (Give them a minute). Now either put on or take off your safety glasses. Sure it can be done, but it sure isn't as easy as when you have a thumb to use. That is the way life changing injuries affect us.

Today as you are out in the facility, think about life changing injuries. Try typing on the keyboard with only your pinkie finger or writing with your less dominant hand or close your eyes when you're eating lunch and imagine that was the way the world looked each and every moment of your life.

That is what life changing injuries are about.

Thursday, June 2, 2011

6/2/2011 CTD's - How Can You Prevent Them?

CTD's - HOW CAN YOU PREVENT THEM?

Cumulative Trauma Disorders (CTD's) are strains that may result from long-term repetitive motion or from continually working in an awkward position. Strains commonly occur in the wrists, arms, shoulders or back, affecting the body's joints and surrounding muscles and tendons.

CTD's are said to be today's fastest growing occupational problem, affecting all types of employees, from computer operators to construction workers. Modern equipment, tools and machinery have increased production capabilities in many ways. But in some cases, they have also increased the potential for strain injuries in people. These disorders not only cause great discomfort, they can also affect a person's employability and personal lifestyle choices.

• Do warm-up exercises before beginning physically demanding tasks (take a tip from athletes).

• Plan ahead, if you will be doing a job that is awkward--think of ways to make it easier.

• Rotate your work position, to change how muscles are used during your work shift.

• Use the proper tool for the job to avoid awkward movements and the need for overexertion.

• Take a rest break when fatigue sets in. Just a few minutes can make a difference.

• Carefully stretch tired or overworked muscles to improve circulation and relieve tension.

• When appropriate, use anti-shock or anti-vibration gloves, back supports, wrist supports, or other personal protective equipment that helps prevent cumulative trauma.

• Always use proper lifting techniques. Back strain is one of the most common CTD's.

• When using hand tools keep your wrists in a "neutral" position, as opposed to repeatedly bending them up, down or sideways during work tasks.

• Just because a co-worker is not affected by a physically demanding task, don't ignore messages your body sends you. Although humans share many physical characteristics, people are often different in terms of their physical strengths and weaknesses.

All muscle discomfort and fatigue is not a cumulative trauma disorder. Everyone experiences occasional aches and pains from both work and play-especially when you are not used to the activity. Nevertheless, awkward, repetitive work positions can result in long-term physical problems, so it's up to you to avoid these in whatever ways you can. If the ache doesn't go away within a day or two, follow the above suggestions.

If you have early symptoms of chronic discomfort, report it immediately to your supervisor. The sooner a better tool or work position can be incorporated into your work activities, the sooner those symptoms can be controlled.

Listen to what your body tells you and learn how to avoid CTD's!

Wednesday, June 1, 2011

6/1/2011 Being Mentally Prepared For Emergencies

BEING MENTALLY PREPARED FOR EMERGENCIES

Would you know what to do if an emergency occurred while you were on the job? Do you know what actions to take if a co-worker was seriously injured, a fire ignited, or a structure collapsed? Are you prepared to react?

Emergencies and disasters are a reality of everyday life. Local and international news programs document such occurrences every day throughout the world. Too many lives are lost and property is damaged because no one was prepared to properly react when immediate decisions and actions counted.

A good start in learning how to respond to an emergency is through certification in Basic First Aid and CPR (Cardio Pulmonary Resuscitation). These courses teach important skills. But even more important than the first aid skills gained, they teach how to respond to an emergency. Programs offered by organizations such as the highly respected American Red Cross teach people about the kind of situations or conditions that might precipitate an emergency. Knowing what to look for and how to react could save the life of a co-worker or family member.

Your company should have an emergency action plan. Familiarize yourself with where to find it, and review it periodically. Be aware of what steps to follow when calling for emergency help. Know the course of action to take in likely emergencies at your facility. This will improve your safety awareness in everything you do.

Safety awareness may be gained through the company's regular safety meetings, safety training or your own personal interest in safety & health. This awareness will increase your ability to respond if, some day in the future, you are a bystander in an emergency. This is particularly important if you work in a hazardous industry. You should be able to answer the following:

How and who do you notify in an emergency?

Are you prepared to react responsibly?

Should you stay with the injured person or run for help?

If you are not First Aid certified, do you know who in your crew or the company is?

Does the emergency scene need to be secured?

Do you know the chain of command? Who's in charge during an emergency?

You come to work every day prepared for the task at hand and knowledgeable on how to handle production problems in the workplace. Being mentally aware is also your best preparation for a potential emergency. Analyze beforehand what to do if one of your co-workers is injured, and if that injury is life threatening. Know how to protect yourself, your co-workers and the company in case of a serious chemical spill. Chances are, during a crisis, you won't have much time to plan the best possible action-so make those decisions ahead of time.

When an emergency does occur, it is your responsibility to be mentally ready.

Subscribe to:

Posts (Atom)